In the world of electronics and industrial applications, precision and performance are key elements that cannot be compromised. Introducing our latest innovation in PCBA manufacturing: the cutting-edge stepper motor driver board. As an essential component designed for industrial applications, this masterpiece combines reliability and efficiency to control stepper motors seamlessly.

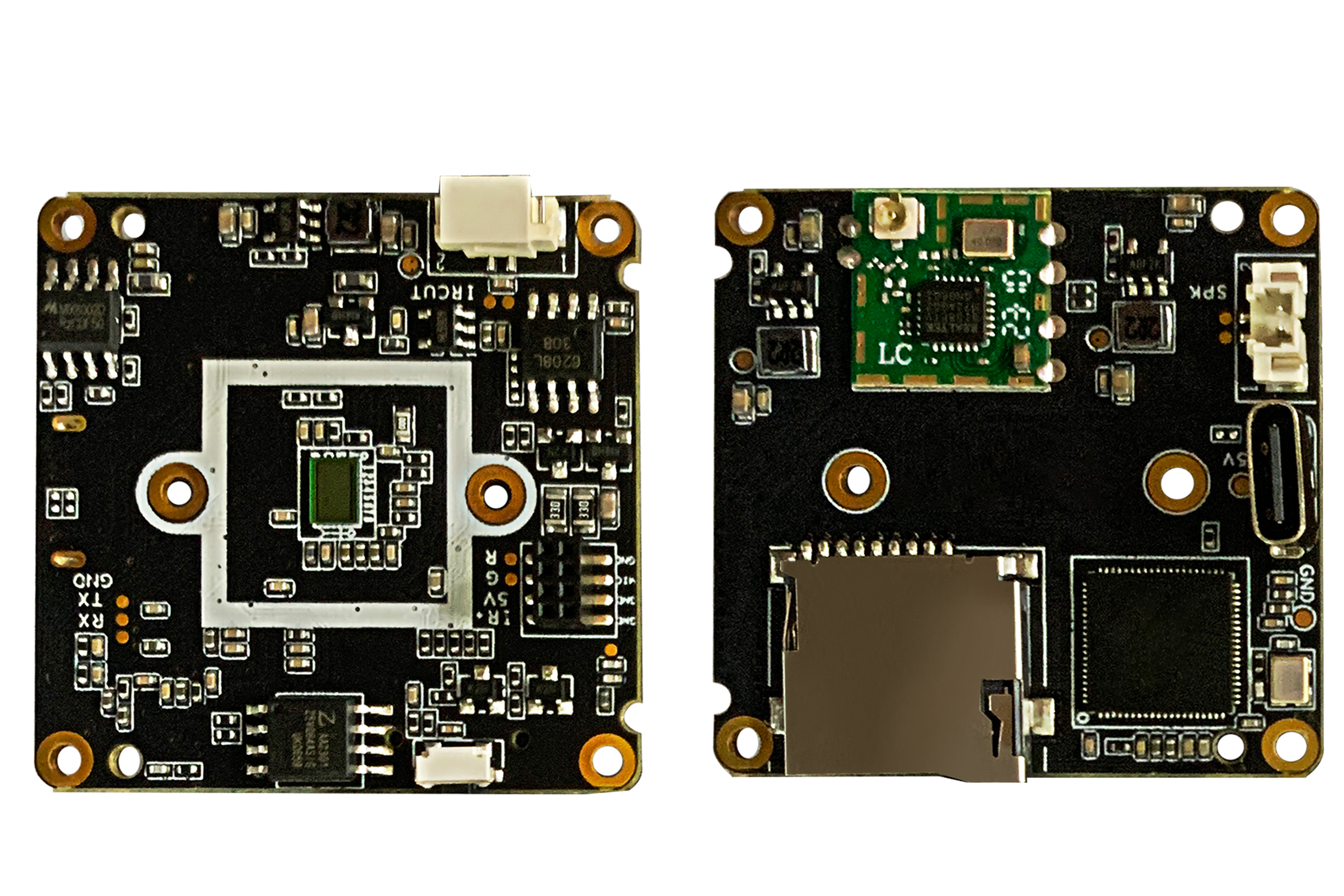

Printed circuit board assembly, often abbreviated as PCBA, involves mounting and soldering components onto a PCB to create functional electronic devices. Our PCB assembly services are renowned for their exceptional attention to detail, ensuring that high-performance integrated circuits are placed meticulously to handle intricate motor control operations. These chips are the heart of the device, providing smooth and precise movement necessary for modern machinery's demanding applications.

Connectivity is a crucial facet of our stepper motor driver board. With an array of pin headers and robust connectors, including dual parallel interface ports, it offers versatile connectivity options. This ensures seamless integration into various setups, allowing easy interfacing with other devices and controllers. The parallel DB connectors facilitate system design's simplicity, empowering users with control right at their fingertips.

Moreover, the board is equipped with multiple LED indicators that provide immediate visual feedback regarding its operating status. This feature is particularly beneficial in high-noise environments, simplifying diagnostics and allowing machine operators to focus on productivity rather than troubleshooting. This intuitive design aligns with our commitment to creating user-friendly yet highly efficient solutions.

For optimal power regulation and signal filtering, high-quality capacitors and resistors are methodically distributed across the board. These components play a vital role in maintaining control signals' stability and accuracy, which is crucial in the realm of industrial automation. The layout is crafted with engineering precision, marked by clear labeling and simplified pathways to ensure the efficiency of design and ease of installation and maintenance.

Furthermore, the green PCB not only highlights our eco-conscious ethos but is engineered for thermal efficiency. Its excellent heat dissipation properties ensure consistent performance even under high-load scenarios. The stepper motor driver board is a testament to industrial elegance, blending form, function, and forward-thinking.

Whether utilized in driving CNC machines or automated conveyor systems, this technology epitomizes trust and performance. By redefining possibilities in industrial automation, our board offers a perfect mix of precision and power. As a leading innovator in printed circuit board assembly, we proudly deliver results with unparalleled efficiency, paving the way for future advancements in reliable electronic solutions.

People who viewed this also viewed

1.Introduction to PCBA Manufacturing 2.Overview of Printed Circuit Board Assembly 3.Role of PCBA Services in Electronics Market 4.Advancements Shaping PCBA Manufacturing 5.Innovations in Products Utilizing PCBA 6.Future Outlook of PCBA in Electronic Industry 7.Conclusion on PCBA's Technological Impact

1.Introduction to PCBA Assembly 2.Core Features of the Microprocessor Development Board 3.Front Facing Components and Their Functions 4.Reverse Side Capabilities 5.Advanced Technical Specifications 6.User Accessibility and Installation Guides 7.Future of Printed Circuit Board Assembly 8.Conclusion: PCBA Assembly Excellence in Tech

1. Introduction to PCBA Manufacturing 2. Advancements in Technology and Design 3. The Role of Anyka AK3918 Processor 4. Connectivity and Customization Options 5. Importance of the SD Card Slot 6. Efficiency in Design for Reliability 7. Conclusion: Embracing PCBA for Innovation

1.Introduction to PCBA Manufacturing 2.Importance of Precision in Electronics 3.Stepper Motor Driver Board Overview 4.Role of Printed Circuit Board Assembly 5.Connectivity Features 6.Visual Feedback with LED Indicators 7.Power Regulation and Signal Filtering 8.Thermal Efficiency and Design 9.Applications in CNC and Automation 10.Conclusion: Future of Industrial Automation