PCBA manufacturing is a fundamental aspect of modern electronics production, serving as the backbone for various devices and technologies. It involves the intricate process of assembling printed circuit boards (PCBs), which are crucial in enabling electronic components to function cohesively within a device. As technology constantly evolves, the demand for sophisticated and precise PCBA manufacturing processes continues to grow.

Printed circuit board assembly, or PCBA, is known for its multifaceted approach to ensuring that each electronic component is accurately placed and securely soldered onto the board. This process involves several crucial stages, starting from design conception, where engineers meticulously plan the layout of the PCB to optimize space, functionality, and performance. Followed by component placement, technicians employ cutting-edge machinery and manual expertise to install components with precision. Finally, soldering and inspection processes demand a keen eye for quality control, ensuring that the finished PCB is free from defects and ready for deployment.

PCBA services are an essential part of bringing innovative electronic products to market. Companies offering these services strive to deliver unparalleled precision and reliability, utilizing advanced technologies such as surface mount technology (SMT) and through-hole assembly to cater to diverse customer requirements. These services are highly adaptable, catering to industries ranging from consumer electronics and telecommunications to aerospace and automotive sectors. By harnessing state-of-the-art technologies, PCBA service providers can offer tailored solutions that support rapid development and deployment of electronics, ensuring a competitive edge in the global market.

The rapid advancements in PCBA manufacturing are paving the way for new innovations like the Digital Pressure Gauge Module, a versatile tool for precision measurement. This module, crafted from a meticulously designed PCB, epitomizes the superior craftsmanship involved in modern circuit board assembly. Its high-contrast digital display, coupled with multi-unit measurement capabilities, showcases the versatility and global applicability of such technologies. Moreover, the module's slim and lightweight design exemplifies how thoughtful engineering in PCB design can result in compact, functional, and aesthetically pleasing technology solutions.

Similarly, the introduction of the HG-003 circuit board highlights the transformative power of PCBA in electronic assemblies. With its robust layout integrating dual USB-C ports, the board exemplifies the advancement of high-speed data transmission and power delivery, which is crucial for contemporary devices. The inclusion of strategic components like microchips and surface-mounted capacitors demonstrates the sophisticated approach taken during PCBA manufacturing to fortify devices against potential system overloads and ensure stable operation. Such innovation in PCBA pushes the boundaries of electronic design, catering to the increasing demand for efficiency and sophistication in technology.

Ultimately, PCBA manufacturing remains at the forefront of electronic production, continually adapting to industry needs and technological breakthroughs. By integrating cutting-edge components and leveraging expert craftsmanship, companies can ensure that their products not only meet but exceed modern technological standards. Whether it's optimizing industrial applications or enhancing everyday consumer electronics, PCBA processes play an instrumental role in shaping the future of technology, offering the precision, reliability, and adaptability necessary to thrive in an ever-evolving landscape.

People who viewed this also viewed

1.Introduction to PCBA Manufacturing 2.Overview of Printed Circuit Board Assembly 3.Role of PCBA Services in Electronics Market 4.Advancements Shaping PCBA Manufacturing 5.Innovations in Products Utilizing PCBA 6.Future Outlook of PCBA in Electronic Industry 7.Conclusion on PCBA's Technological Impact

1.Introduction to PCBA Assembly 2.Core Features of the Microprocessor Development Board 3.Front Facing Components and Their Functions 4.Reverse Side Capabilities 5.Advanced Technical Specifications 6.User Accessibility and Installation Guides 7.Future of Printed Circuit Board Assembly 8.Conclusion: PCBA Assembly Excellence in Tech

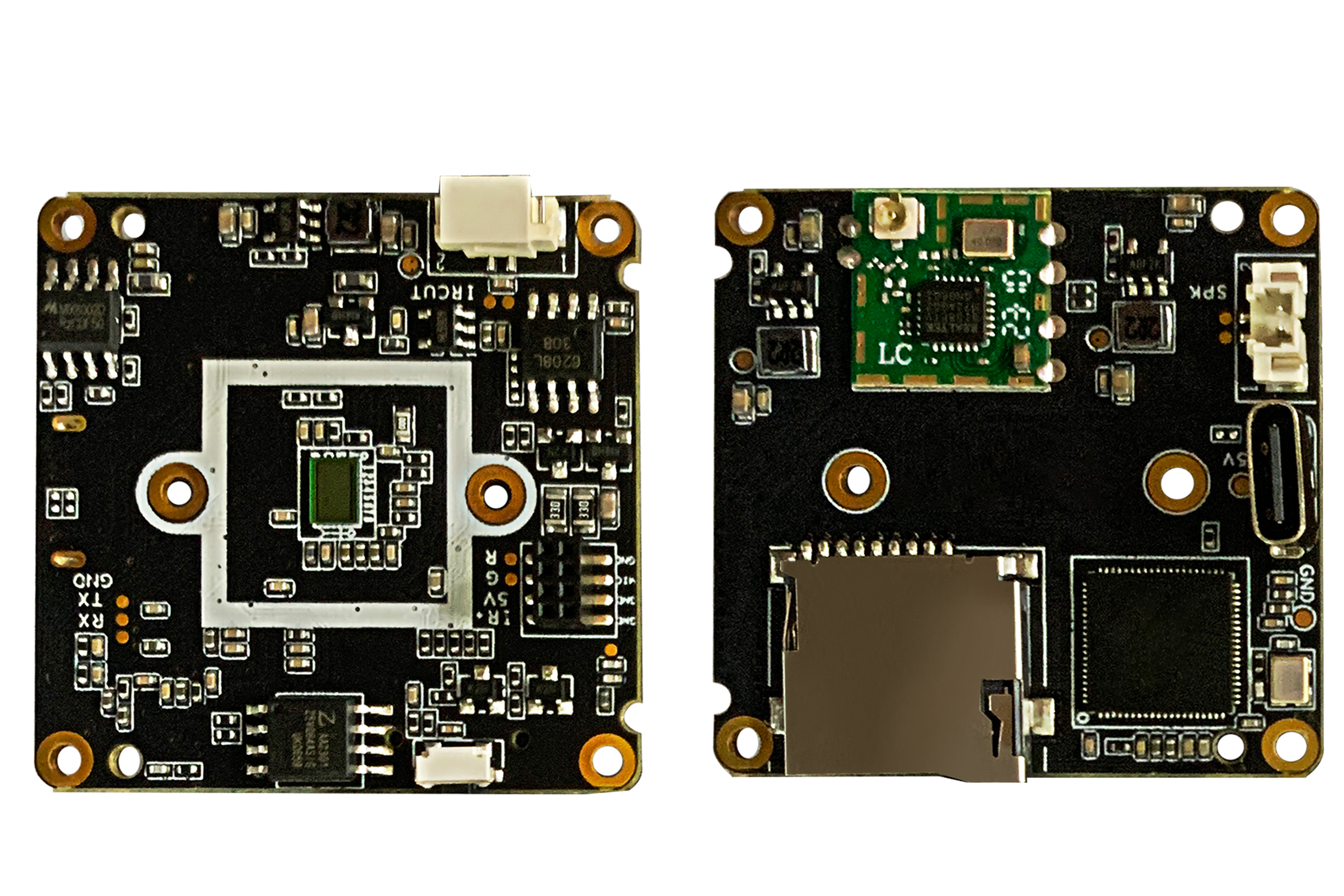

1. Introduction to PCBA Manufacturing 2. Advancements in Technology and Design 3. The Role of Anyka AK3918 Processor 4. Connectivity and Customization Options 5. Importance of the SD Card Slot 6. Efficiency in Design for Reliability 7. Conclusion: Embracing PCBA for Innovation

1.Introduction to PCBA Manufacturing 2.Importance of Precision in Electronics 3.Stepper Motor Driver Board Overview 4.Role of Printed Circuit Board Assembly 5.Connectivity Features 6.Visual Feedback with LED Indicators 7.Power Regulation and Signal Filtering 8.Thermal Efficiency and Design 9.Applications in CNC and Automation 10.Conclusion: Future of Industrial Automation